Maintenance

Elevating Industrial Maintenance

Stuart Olson’s Maintenance, Repairs, and Operations (MRO) division is committed to delivering top-tier maintenance, turnarounds and capital project solutions that revolve around continuous improvement. Our focus is centered on helping you achieve your goals in asset reliability, talent retention, marketing, quality, and safety.

We have positioned ourselves to gather insights from diverse market conditions and share best practices, across Canada’s leading projects. We aim to extend our expertise to all project sites, working collaboratively to innovate and optimize processes, tooling, equipment, materials, and labour.

Our Service Portfolio

Core Services

- Mechanical

- Electrical

- Instrumentation

- Insulation

Ancillary Services

- Specialty mechanical (i.e., Bundle pulling/ heat exchanger)

- High voltage

- Powerline

- Sheet Metal

- Cladding

- LDAR and M-21 Compliant Emissions Management

- Overhead or Underground Distribution & Transmission

- Dry Ice Blasting

- Asbestos Abatement

What We Deliver

- Single or Multi-Discipline Services

- Embedded & Non-Embedded Models

- Dedicated Workforce Planning & Recruitment

- Employee Competency & Development Program

- Optimized Planning & Scheduling

- Continuous Improvement Programs

- Maintenance Acceptance Testing

- Award-winning HSE Performance

Turnarounds

The Pursuit of Continuous Improvement

Our track record speaks volumes about our ability to plan and execute projects precisely on schedule and within budget. In the pursuit of project success, daily reporting becomes a cornerstone. Our robust and transparent project controls system delivers vital, real-time progress reports, enabling you to make informed, proactive decisions that keep your project on track.

Turnaround Expertise

- Dedicated Workforce Planning & Recruitment

- Continuous Coverage with All Disciplines

- Planning & Scheduling

- Turnover Planning/ Equipment Inspections

- Supervision, Quality, Safety, Administration

- Daily Reporting & 3-Day Look Ahead

- Commissioning & Start-up

- Regional Labour Planning

- Found Work Response

- Logistics and Procurement

- 3rd Party and OEM Management

Core Services

The MRO group specializes in multi-disciplinary maintenance, turnarounds, and sustaining capital projects executing work in Canada’s various Industrial sectors.

Our primary focus is providing skilled craft labour services through bundled and optimized labour solutions.

Core Service Expertise:

- Mechanical

- Electrical

- Instrumentation

- Insulation

- Cladding

Specialty Services

For over 100 years, we have provided maintenance, turnarounds, and construction solutions to the Canadian market, offering a full spectrum of services.

The MRO group delivers several specialty services focusing on asset reliability and uptime.

Specialty Services:

- Project Coordination & Management

- Turnaround Planning & Coordination

- Bundle Pulling and Cleaning

- High Voltage & Technical Services 480V-500kV

- Acceptance & Maintenance Testing

- Specialty Cable Testing & Terminations

- Specialty Transformer Services

- Infrared Inspections (Mechanical & Electrical)

- LDAR, and M-21 Compliant Emissions Management

- Powerline 13.8kV-260kV

- Overhead or Underground Distribution and Transmission

- Heat Exchanger Repairs

- Asbestos Abatement

Safety

Our Safety Reputation

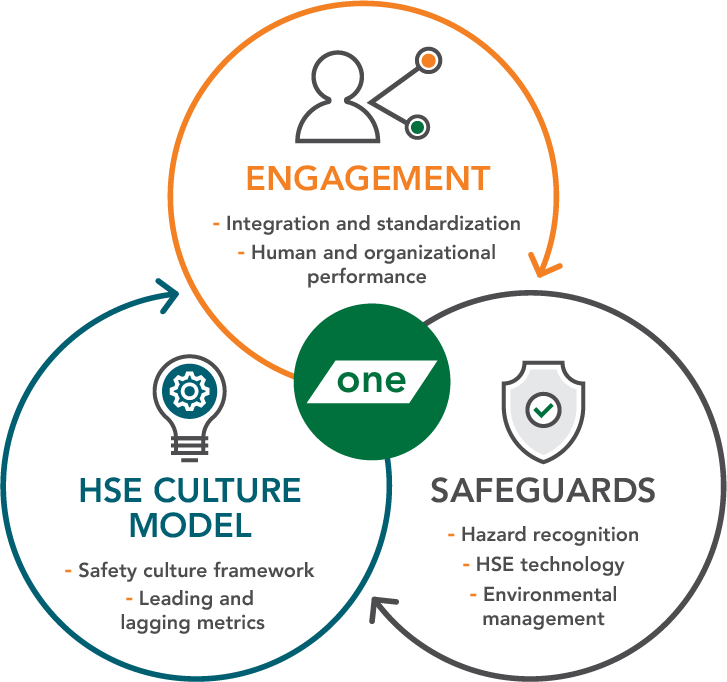

We build a culture of operational and psychological safety through engagement, learning and leadership. We are incredibly proud of how personal ownership is reflected in our safety performance and our well-deserved reputation among our clients and peers.

Our Safety Pillars

Engagement:

- Our workforce is motivated and meaningfully engaged in safety through practical, standardized, and effective programs.

Culture:

- Our employees thrive in a healthy safety culture supported by fair, accurate and timely decision-making.

Safeguards:

- We equip our workers to ensure safeguards are always present, and we measure our success on the effectiveness of those safeguards. Our safeguards are both Safety and Environmentally focused.

Active Safety Memberships

Quality

Our Quality Commitment

At the core of our values, we hold a passion for excellence, not only in our work but also in the relationships we cultivate. Stuart Olson’s Quality Management System stands as a testament to our commitment to ensuring that every project is handed over with consistent quality that sets industry standards. We achieve this through a blend of pragmatic and inventive planning techniques, a commitment to enhancing employee competencies, and a relentless pursuit of continuous improvement strategies.

Our QMS follows ISO 9001:2015 requirements. With 110 approved weld procedures and 100 multi-discipline QAQC procedures, Stuart Olson is the complete choice for dedicated and proactive quality work.

Stuart Olson is certified to operate in accordance with the following codes and reference standards: ITSM, TSASK, ASME, ABSA, TSBC, CWB (W47.1/W59)

Our Certifications

Mechanical Certifications / Capability

- “S” Stamp – Manufacture and assembly of power boilers.

- “U” Stamp – Manufacture of pressure vessels

- “U2” Stamp – Manufacture of Class 1 and Class 2 pressure vessels

- ABSA (AQP-1612)

- ASME Section VIII-1 Pressure Vessels

- ASME Section I Power Boilers

- ASME Section IV Heating Boilers

- API 530 & ASME B31.3 Direct Fired Heaters

- ASME Section I Direct Fired Heaters

- ASME B31.3 Indirect Fired Heater Coils

- ASME B31.1 Boiler External Piping

- ASME B31.1 Power Piping

- ASME B31.3 Process Piping

- ASME B31.5 Refrigeration Piping

- ASME B31.9 Building Services Piping

- CSA Z662 Steam Pipelines

- Category A,B,C,D,E,H Fittings

- ABSA (AOQP-7356) PQ Testing of Welders

- Machine Welding Operators

- Pressure Tack Welders

- Pressure Welders

- TSBC – License No. LBP024168 (Scope equivalent to ABSA AQP-1612)

- TSASK – QCP-0226-0002 (Scope equivalent to ABSA AQP-1612)

- ITSM – MB-17-067 (Scope equivalent to ABSA AQP-1612)

- CWB Division III Letter of Validation

- CSA W47.1 & CWA W59.1

- ISO 9001:2015 Compliant

- WPS Registrations in all above-listed Jurisdictions

- Multiple Certified CWB Welding Supervisors

- Multiple CSA W178.2 Welding Inspectors (Level I/II/III w/ numerous code endorsements)

- ISO 9001:2015 Compliant

- CAN/CSA C22.1 Compliant

- ANSI/NETA ATS Compliant

- Argus Pressure Switch Testing & Calibration Certified

- NEMA VE 2 Compliant

- TSBC Licensed Electrical Contractor

- NIST Compliant (Monitoring/Measuring Equipment)

- ECAA Contractor Member

- IEEE Compliant

- Licensed Electrical Contractor with the Government of Saskatchewan

- Various Municipal Jurisdictional Requirements Experience

- Swagelok Tube Fitting & Installation Trained Personnel

- Multiple Certified Master Electricians (RME/CME)

- Multiple Certified Engineering Technologists (CET- Electrical Discipline)

Careers

Grow With Us

We are a premier provider of Industrial Maintenance services with growing and repeat clients, which means that we have a steady stream of work for our employees.

Be a part of our team, where we pride ourselves on the quality of our work and the way we treat each our and our partners. You will build a career and long-lasting relations based on respect, collaboration, and a solution-focused mindset. Unlock your potential and set up your future.

About Us

Stuart Olson has been empowering Canadian business since 1911. Rooted in a solid foundation, we adapt and grow to face the future. We are committed to elevating each other to chart the best path forward in an evolving world.

Stuart Olson and and Bird Construction have joined forces to create a leading Canadian construction company. The combination of two historic Canadian companies, with strong, experienced workforces, offers greater diversification in the integrated suite of construction services, end-markets, and geographies. Our dedication and passion for delivering best in class projects has not changed, nor has our relentless focus and commitment to safety. Our new organization will continue to provide the same high level of service and commitment that you have come to expect.

For shareholders, more information can be found on the Investor Relations page and the Bird Construction website.

Contact Us

Contact us directly to set up a consultation to explore whether our services meet your needs.